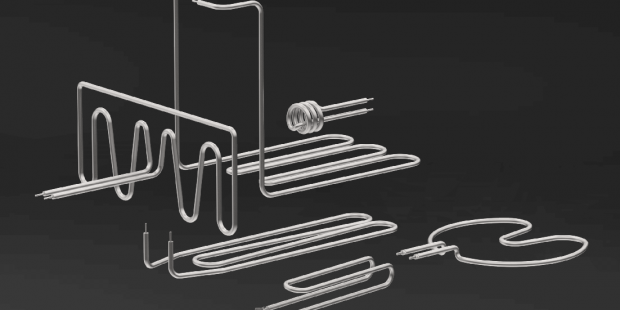

There are many heating elements available in the market, but the tubular heater is the most well-known among them. They can be formed into any configuration. These heating elements transfer heat by convection, emission, and transmission to heat surfaces, liquids, gases, and air.

These heaters operate through significantly less electricity and are much safer, cleaner, and cheaper than paraffin. You may create a thermostat to maintain a constant level of the temperature of the tubular heaters.

Effective uses

This heating element is used for:

- Heating the oil, gas, and air

- Clamp-on heating

Places of use

This heating element is used in various industries starting from residential use to retail food. In these places, oil, grease, air, and water need to be heated, and the tubular heater serves their purpose.

For industrial use, the stainless steel in the heater is best for the job. The stainless steel helps to use strong bases and acids. For the harshest environment, a tubular heater uses titanium sheaths.

Benefits of this heating element

There are also some benefits that you can get from the heater. Such as:

- The advance mechanism does temperature maintenance and transfer of heat.

- They are very conveniently installed, easily maintained and cleaned.

- They are also exchanged in case of severe damage.

- Available in various sizes and shapes.

- Designed with advanced technology

- Longer longevity

Temperatures they can reach

These heaters can reach a temperature of 120 c. This high temperature can be achieved because the heaters’ surface is made up of lightweight aluminum. You are recommended to fit all the guards the heater has to avoid anyone coming in contact with the heaters.

Installation process

The wiring must be according to the NEC (National Electrical Code). The appropriate wire must be used because this heater can reach a very high temperature. The wire must be long and strong enough; else it can break because of overheating. While choosing the wire, you must be sure about the temperature and insulation. The wiring must be tight enough to the thermals.

Mounting methods should also be done carefully through the ovens and the walls of the tanks. Field installation is effortless and must be done with compression.

These heaters use minimum electricity and do their job correctly. They fall into the category of electrical heaters. These heaters are used in various industries where heating is done.